Non Ferrous Scrap Metal Separator Material Separation Test

The annual output of RUIJIE precision mon ferrous scrap metal separation equipment is more than 1,000 units, with more than 13 patented technologies, and customers are all over the world in various industries, and are well received by users.

It has been rated as a leading enterprise in solid waste sorting by industry associations for 7 consecutive years. Our independent research and development production of Non Ferrous Metal Separator has the following characteristics.

1. Excellent Magnetic Material, Excellent Quality:The Non Ferrous Metal Separation Equipment is made of excellent magnetic materials, with large permeability, high quality and long service life.

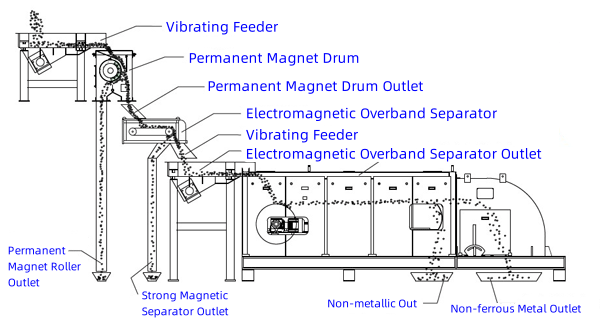

2.Reasonable Structure and Flexible Configuration:The eddy separator structure design is reasonable, with complete model, flexible configuration, to meet the sorting needs of different materials.

3. Cost-effective, Wide Range of Uses:Ruijie non ferrous metal separator has high cost performance, mainly used for scrap metal recycling, to meet the needs of a variety of industries.

4. High Sorting Rate, High Work Efficiency: This scrap metl separator is equipped with fast sorting speed, high accuracy and high work efficiency, effectively shorten the construction period.

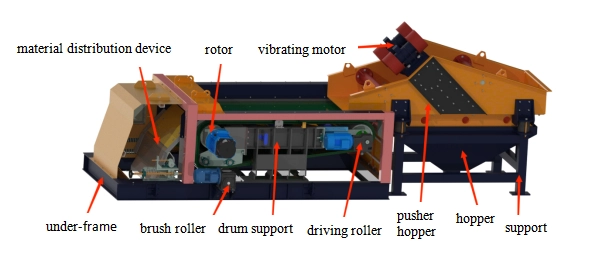

5. Height and Angle Adjustable:According to the requirements of belt speed and material size, the height and angle of the material distribution plate can be adjusted.

6. Matching vibrating feeder: Each eddy current separator gets a matching vibrating feeder to ensure that the material enters the eddy current sorter in a uniform and continuous state, so as to achieve the best sorting effect.

RUIJIE Non Ferrous Scrap Metal Separator Belt

RUIJIE Seamless Skirt Conveyor Belt

The common conveyor belt with lap skirt tend to tear easily during use, causing spillage and leakage more often, which is completely unable to be used normally.

We have always chosen seamless skirt conveyor belt, which neither leak nor spill materials, leading to higher sorting efficiency.

RUIJIE Conveying Belt Has Good Abrasion Resistance

Since most transported materials are non-ferrous metals, conveyor belts require high wear resistance. Ordinary belts tend to scratch easily, have a short service life, and need frequent replacement. In contrast, our high-quality belts incorporate high-strength wear-resistant materials, offering superior abrasion and scratch resistance—ultimately reducing customers’ production costs.

RUIJIE Conveying Belt Has Good Magnetic Penetration

Some conveyor belts are doped with recycled materials in raw materials, resulting in poor magnetic permeability. In contrast, our conveyor belts are made of high-quality raw materials, with good toughness and no fracture. This design enhances magnetic permeability by 50%, delivering superior operational performance.

Key Considerations for Inspecting and Operating an Eddy Current Separator During Operation

1. During normal operation of an eddy current separator, in the event of a sudden shutdown, the equipment must not be restarted forcefully until the cause of the shutdown has been identified.

2. After identifying the cause, the materials on the non-ferrous metal separator must be cleared out before the equipment can be restarted in an orderly manner.

3. During operation, monitor the sound of the non-ferrous metal separator for normality. Immediately address abnormal noises such as scraping or friction, and strictly prohibit inspecting the equipment while it is in operation.

4. After the non ferrous metal separators and vibratory feeder are shut down, the wear of the belt and sieve plate should also be checked. Only after the inspection of each of the above parts is normal, the start-up signal can be given, and then the device is started sequentially.

PURCHASE COST – EFFECTIVE SCRAP METAL SEPARATION EQUIPMENT HERE