Used Beverage Cans (UBC) Recycling

Professional Manufacturer Of Used Beverage Can (UBC) Sorting Equipment

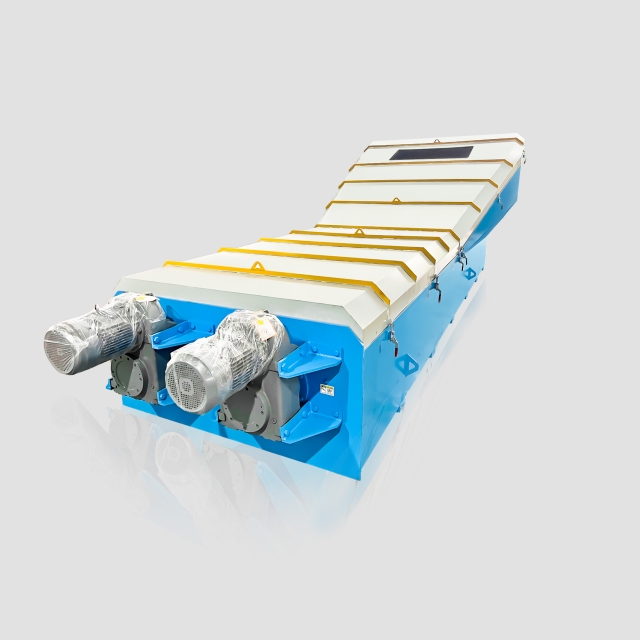

We specialize in the production of magnetic separation equipment, eddy current separators, etc., focusing on the research and manufacture of sorting equipment machines in the field of recycling.

In order to meet the needs of the plastic bottle recycling industry and the beverage aluminum can recycling industry, we provide a variety of equipment suitable for the plastic and beverage can recycling business. We’re here to breathe new life into your plastic bottle and beverage can recycling process!

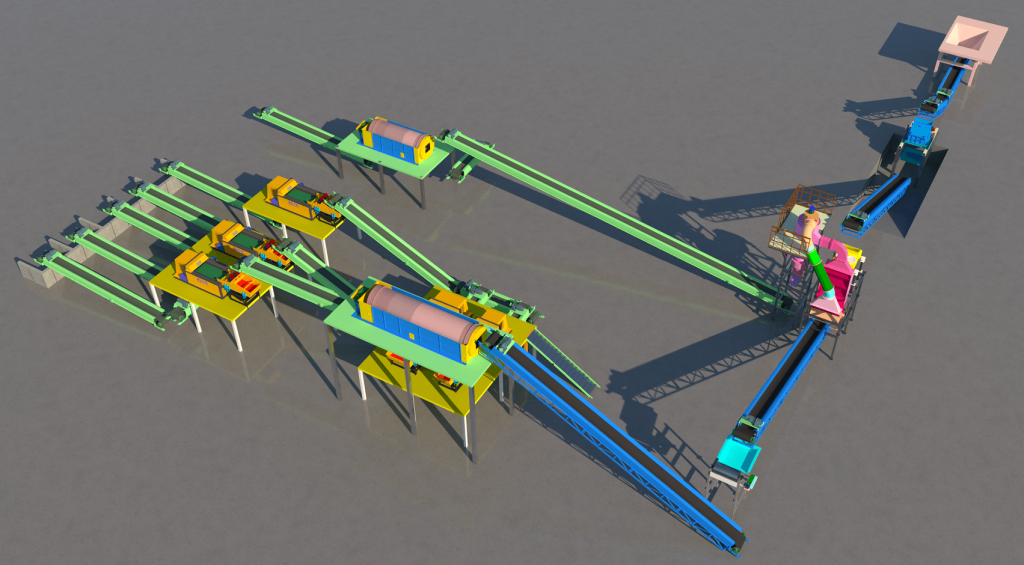

Standard Waste Beverage Can Recycling System From RUIJIE

We can customize the beverage can recycling process according to the different needs of customers, and can provide a complete set of machinery and equipment to design and produce sorting solutions free of charge.

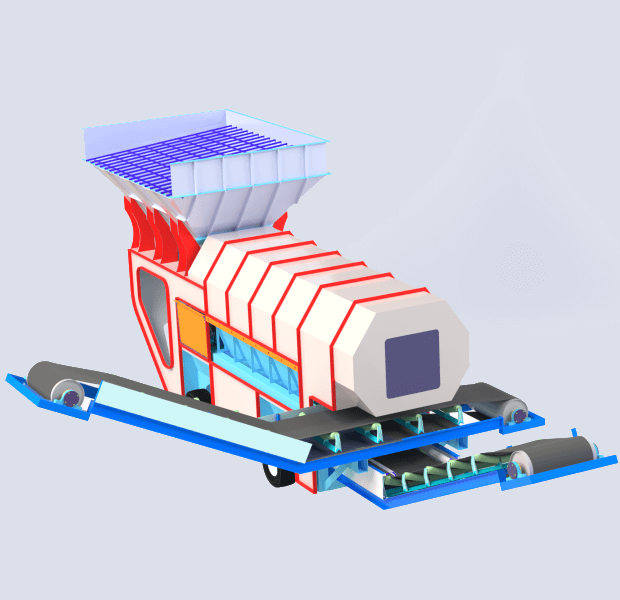

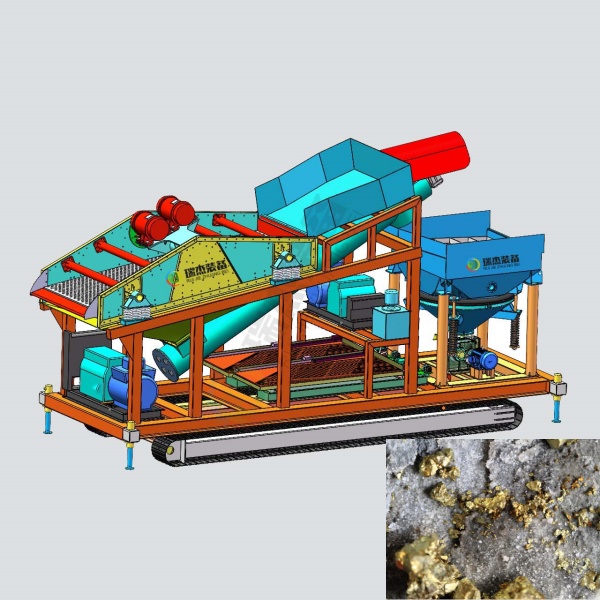

The removal of metal is an important step in the recycling process of plastic bottles and aluminum cans. The following two types of equipment are specially designed for bottle recycling, including iron can sorting equipment, aluminum can sorting machine. It is mainly used to remove metals through a circular process. These technologies are used in conjunction with each other throughout the recycling process to achieve your desired results.

What is Used Beverage Cans(UBC)?

Used beverage can (UBC) waste refers to aluminum cans that are discarded after use. UBC scrap is a valuable resource for the recycling industry because aluminum cans are 100% recyclable and can be reused indefinitely.

What Are The Benefits Of Recycling Cans?

The recycling of cans can not only save bauxite, but also save 97% of energy, which has a great contribution to the protection and beautification of the earth’s environment.

The recycling process for UBC scrap typically involves sorting, cleaning, and melting the cans to produce aluminum ingots or sheets. These ingots and aluminum sheets can then be used to produce a variety of new products, such as new beverage cans, car parts, building materials, and other consumer goods.

Recycled aluminium ingots can be made from cans and cans from recycled ingots can be recycled many times. No matter how many times the cans are recycled, the quality will not be compromised. Because many people will worry that the quality of the recycled product will be a little worse, but it will not. After the cans are melted, the chemical composition of the recycled ingots produced remains the same as before, with little change.

What Happens To Waste Bottles After Recycling?

Bottles of different materials are sent to recyclers and then collected at material recovery facilities (MRFs). For example, aluminum cans, steel cans, glass cans, and plastic bottles can all be classified into different raw materials.

For example: Aluminum cans can be made into new beverage cans, space shuttles, window frames, etc.; Scrap steel cans can be made into rolled bar, new steel cans, new bicycles, or new steel beams; Waste glass jars and glass bottles can be made into new glass jars and glass bottles; Plastic bottles can be made into new plastic bottles, food-grade plastic boxes, and even synthetic fiber clothes.

Offer A Variety Of Waste Beverage Bottle Recycling Solutions

RUIJIE ZHUANGBEI offers the best equipment for disposing of the waste beverage materials you are disposing of.

Please do not hesitate to contact us and send us your wishes and requirements. For example: different raw materials, different outputs, different recycling system specifications, etc. We can provide recycling equipment solutions for aluminum can recycling, PET plastic bottle recycling, glass jar recycling and other applications to purify waste bottle products of different materials.

According to the recycling needs of different customers, we provide different recycling solutions!Standard solutions range from 3,000-10,000 kg/production hour and are often the starting point for customizing solutions for larger capacities or other special requirements.

RUIJIE’s aluminum recycling systems are known for their high performance, low production costs, and high metal purity.

The system and machine were developed based on environmental mechanical technology to reduce and separate the size and remove iron and other impurities without the need for melting or chemical treatment.