Magnetic Overband Separator Field Application

There are two types of hanging installation methods, inclined and horizontal, both of which are related to the iron separator working at the relevant position of the conveyor belt.

Horizontal Installation

This Electromagnetic Overband Separator is suspended on the assembly line with a wire rope, and the height between the track and the conveyor belt can be adjusted by adjusting the wire rope on the hanging lug.

Magnetic Materials Separated by Overband Magnetic Separator

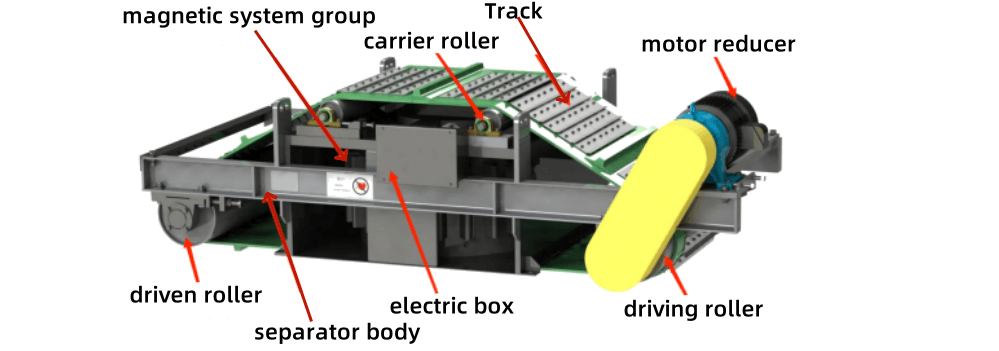

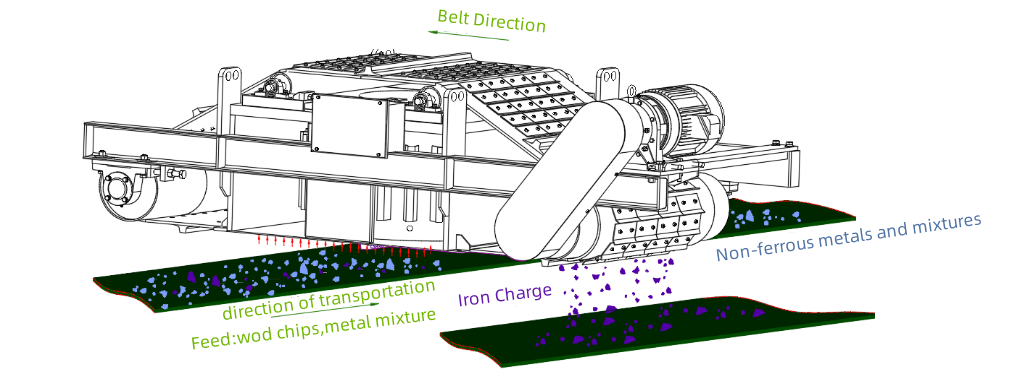

RUIJIE Belt suspended magnet is a kind of electromagnetic equipment used to remove iron parts from non-magnetic materials. The Suspended Permanent Electromagnetic Magnet is composed of magnetic system, shell and other parts, and is an environmentally friendly, high-efficiency and energy-saving iron removal equipment.

The following magnetic materials, including large and small iron blocks, were separated from the customer’s incineration bottom ash separation plant, household appliance waste plant, and construction waste recycling plant by using RUIJIE Suspended Overband Magnetic Separator.

Our Magnetic Overband Separators can work continuously without failure even in harsh environments, with low failure rate, large magnetic permeability depth and strong suction.

Iron is Removed From Incineration Bottom Ash (IBA)

In the video, our Electromagnetic Magnet Machine is applied to the IBA selection line, featuring continuous and automatic iron removal—no manual restart is required after the initial startup. In addition, the magnetic field strength is adjustable via the control cabinet, which is constructed from 304 stainless steel—corrosion-resistant, rust-proof, easy to clean, and resistant to dirt accumulation in humid environments.

The rotating belt of our machine features a unique armored design, which effectively prevents the belt from being cut by sharp ferromagnetic substances during operation. This design ensures greater stability and durability, thereby enhancing sorting efficiency and extending service life.

Precautions Are Required During The Working Process of the Electromagnetic Overband Separator

1.Before the Work of The Electromagnetic Iron Remover: Before operating the electromagnetic iron remover, inspect all components to check for loose screws, broken belts, and aged or damaged wires

2.During the Working Period of the Machine: It is essential to regularly inspect electrical control indicators for normal operation, the excitation performance of the electromagnetic iron remover for optimality, and environmental factors (ambient humidity, air temperature, equipment operating temperature)—all critical to ensuring proper excitation.

3.After Stopping:under normal circumstances, after the excitation of the permanent magnet iron remover is completed, the ferromagnetic impurities should be stopped immediately, and the electromagnetic iron remover should be powered off immediately to remove the impurities.

What Are The Common Faults Of Electromagnetic Overband Separator ?

|

Common Fault |

Reason Analysis |

Elimination Methods |

|

The belt is loose |

The belt is used for a long time, and the tension force becomes longer |

Loosen the fixing screws of the four bearing seats of the two idlers, and twist the adjusting screws of the idlers so that the idlers are pushed outwards. When the belt is tensioned, tighten the fixing screw of the roller |