Customizable Dewatering Screen Customer Field Application

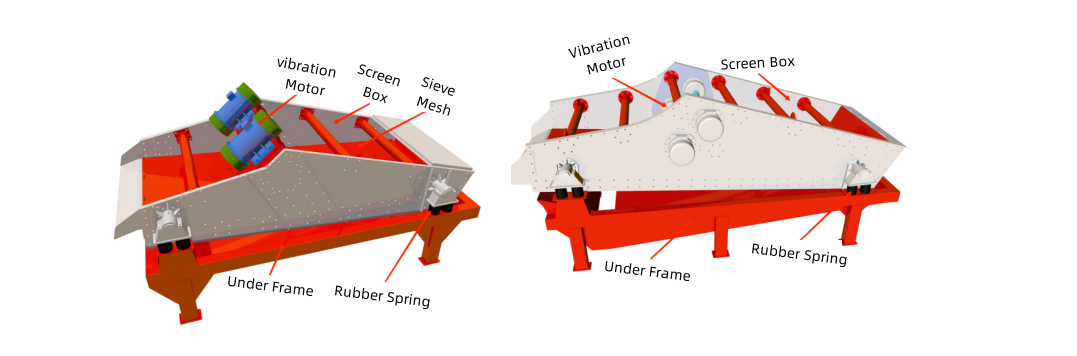

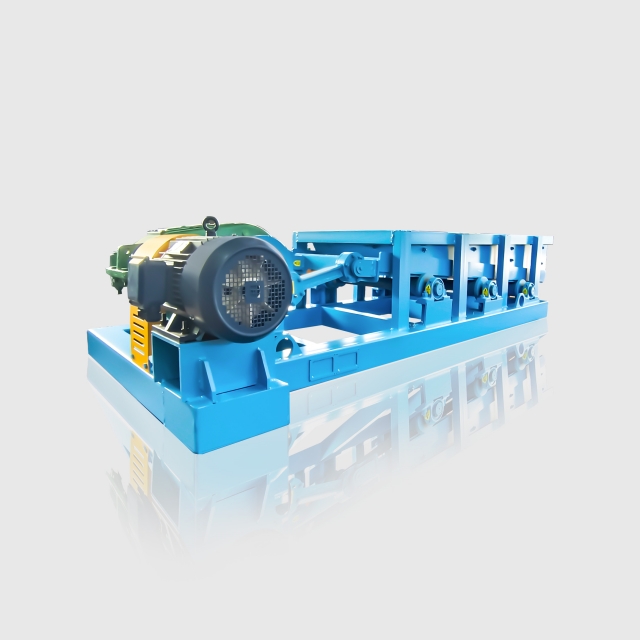

When the double motor series dewatering screen is operated by two vibrating motors synchronously and in reverse, the excitation force generated by the eccentric block cancels each other in the direction parallel to the motor axis.

It is stacked as a resultant force in the direction perpendicular to the motor axis, so the movement trajectory of the material on the linear vibrating dewatering screen machine is a parabolic motion in a straight line, and the two motor shafts have a certain inclination angle relative to the screen surface, and the material is thrown up on the screen surface under the action of the excitation force to make a linear movement, so as to achieve the purpose of screening and grading the material and dehydration.