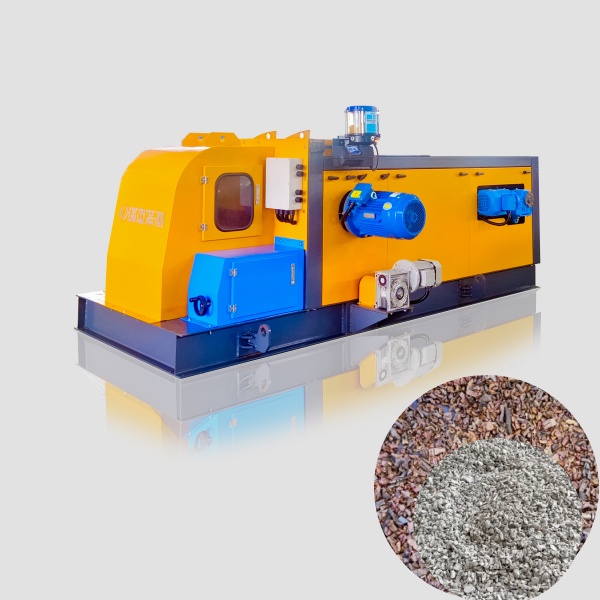

How about Ruijie Eddy Current Separator Machine Testing for Aluminum Recycling?

The eddy current separator machine is a highly efficient and innovative piece of equipment widely utilized in the field of metal recycling industries to recover non-ferrous metals, such as aluminum, copper, and zinc, from mixed waste streams.

Ruijie Eddy Current Separator Machine Testing

| Test Item | Test Samples | Description of Test Situation | Test Results |

|---|---|---|---|

| 1 | Thin aluminium sheets and rubber sheets | Aluminium sheets, as non – ferrous metals, were repelled by the magnetic field and jumped forward along the conveying direction, achieving successful separation from rubber sheets. | Separating purity rate of over 99% |

| 2 | Mixture material | Non – ferrous metals like aluminium in the mixture were pushed forward by magnetic repulsion, separating from non – metallic substances. | Overall separation efficiency of around 99%. |

| 3 | Aluminium flakes and plastic bottle shreds | Aluminium flakes, influenced by magnetic repulsion, leaped forward along the conveying path, getting separated from plastic shreds. | The separation of aluminium flakes from plastic shreds was completed. |

| 4 | Aluminum cans | Due to the magnetic field’s repulsive force, aluminum cans jumped ahead in the conveying direction, separating from other materials. | All aluminum cans were separated cleanly, none left. |

| 5 | Aluminum cans and plastic bottles | The magnetic field’s repulsion made aluminum cans jump forward along the conveying direction, realizing separation from plastic bottles. | Separation accuracy of over 99%. |

Core Working Principle of Eddy Current Separator Machine

The eddy current separator operates via electromagnetic induction and Lorentz force principles. A high-speed rotor with NdFeB magnets generates a rapid alternating magnetic field (up to 4,200 Gauss in Ruijie systems), inducing eddy currents in conductive metals like aluminum.

These currents create opposing magnetic fields, producing a repulsive Lorentz force that ejects metals from non-conductive materials. This mechanism enables efficient recovery of high-purity aluminum and non-ferrous metals for remelting, significantly reducing reliance on virgin metal extraction and lowering environmental impacts from mining.

Key steps include magnetic field generation, eddy current induction, and force-driven separation, ensuring precise sorting across industrial recycling applications.

Industrial Applications for Aluminum Recovery

- Eddy current separators excel in diverse recycling scenarios:

- Municipal Solid Waste: Separating aluminum cans from mixed waste streams.

- End-of-Life Vehicles: Recovering aluminum from shredded car fragments.

- E-Waste Recycling: Extracting aluminum from circuit boards and electronic components.

- Construction Waste: Sorting aluminum frames from demolished structures.

Conclusion

Eddy current separators leverage electromagnetic principles to achieve high-purity aluminum recovery, driven by material conductivity, rotor design, and operational precision. Their adaptability across industries—from urban waste management to automotive recycling—underscores their critical role in sustainable resource recovery. Future advancements may focus on enhancing fine-particle handling and energy efficiency to further solidify their position in circular economy frameworks