The question of how to boost efficiency of recycling for secondary use, minimize environmental pollution, and reduce reliance on landfills has become a critical global challenge.

With waste generation outpacing traditional disposal methods, innovative solutions are essential to transform “waste” into valuable resources— a goal where technologies like those from Ruijie are making significant strides.

Why Recycling Matters

Waste from manufacturing, food, construction, electronics, and textiles grows annually. Beyond wasting valuable resources, it harms ecosystems: incineration pollutes air; landfills contaminate soil and water. Achieving high efficiency of recycling is not just an environmental duty—it is an economic opportunity, turning discarded materials into raw inputs for new production, reducing costs, and curbing reliance on virgin resources.

Moving Beyond Manual Sorting

Traditional hand-sorting is slow, costly, and imprecise, with risks of exposure to toxins. Modern equipment— range of eddy current separators and sorting systems offers a superior alternative, combining precision, speed, and safety to redefine efficiency of recycling.

How to Improve Efficiency of Recycling

Electronics Recycling

Electronics recycling involves collecting and processing discarded electronic devices like smartphones, laptops, TVs, and batteries. It contains various components such as metals (copper, gold, silver, aluminum), plastics, glass, and circuit boards. Recyclable materials include precious metals from circuit boards, copper wiring, plastic casings, and glass from screens.

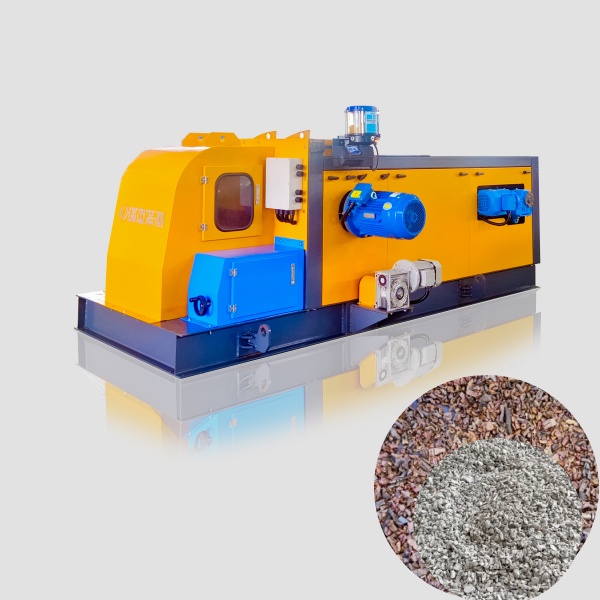

The processing typically starts with sorting to separate different devices, followed by dismantling to remove hazardous parts (like batteries). Then, crusher equipment breaks down the devices into smaller pieces, and separation techniques (such as magnetic separation for metals and density separation for plastics) are used to extract valuable materials, which can be reused in manufacturing new electronics, reducing resource waste and environmental pollution.

Automotive Recycling

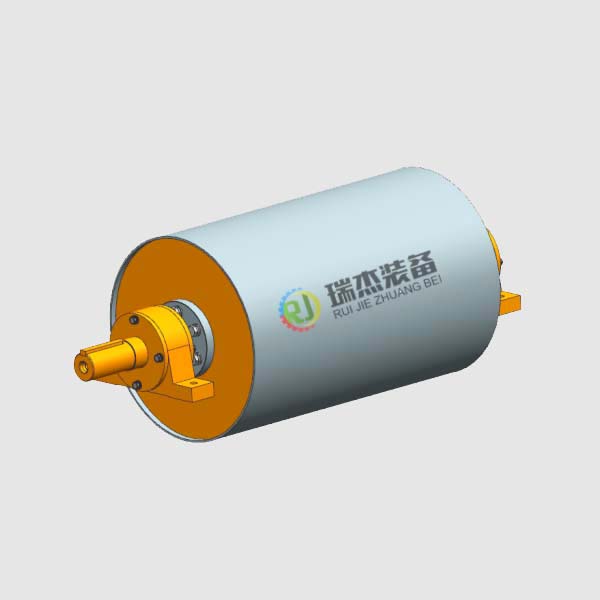

End-of-life vehicles contain a mix of materials: steel frames, aluminum parts, and lead-acid batteries. Separating these manually is time-consuming and error-prone. The scrap automotive after crushing, the steel frame, aluminum parts in the shredder residue can be separated by the magnetic separators and the eddy current separator. This streamlines recovery of valuable metals, reducing the need for new mining and lowering the automotive industry’s environmental footprint.

Food Industry

Food packaging—plastic films, cans, aluminum cover, and metalized wrappers—is a common waste stream. Ruijie’s eddy current separators high effectively separate the aluminum from the mixtures. This allows both materials to be recycled into new packaging or other products, closing the loop on single-use waste.

Construction Waste

Construction waste, such as concrete with steel reinforcing bars or stainless steel aggregates, holds untapped value. After crushing by the crushing machines, electromagnetic overband separators enable to move the magnetic metals like steel, iron lumps, while permanent magnetic separators absord fine iron powder for recovery.

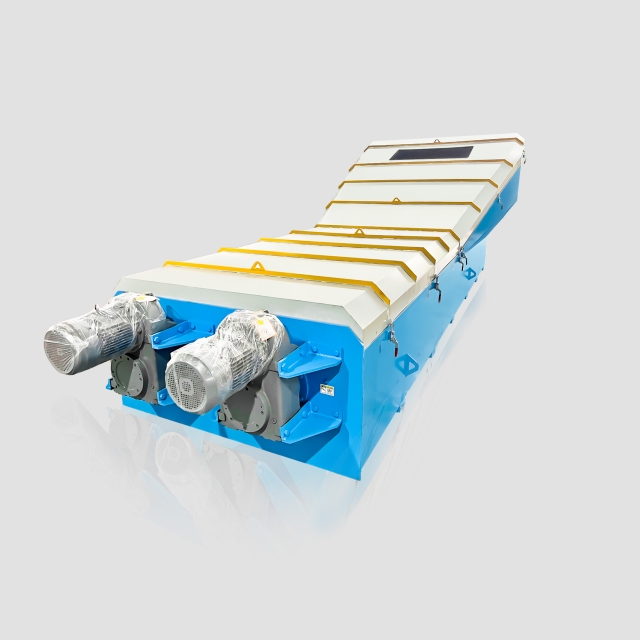

Aggregates are processed by the spiral sand washer and dewatering screen to remove impurities and dehydration, thus obtaining finished sand for new construction materials or road bases. This not only reduces landfill waste but also cuts the construction industry’s demand for virgin steel.

Incineration Bottom Ash and Mining Tailings

Incineration bottom ash(IBA) or mining tailings usually contain iron, copper, gold, silver, aluminum, and other non-ferrous metals. For these multi-component materials, Ruijie’s wet separation line delivers optimal results.

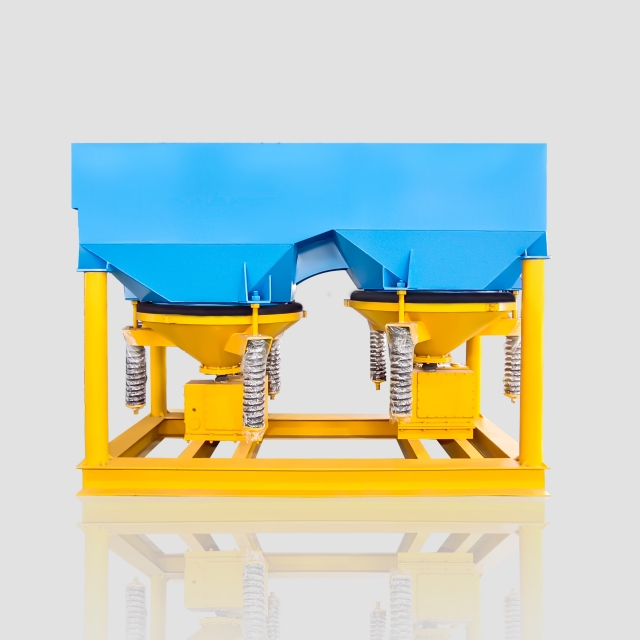

First, a hammer crusher breaks large chunks, while a trommel screen sorts the materials by size. Jig separators use specific gravity to extract heavy metals like gold and silver. Eddy current separators target aluminum, leveraging magnetic repulsion for precise separation.

Ferrous metals are handled by electromagnetic overband separators for larger lumps, with permanent magnetic separators remove fine iron particles.

Remaining aggregates are washed and removed impurities in a spiral sand washer and dehydrated by dewatering screens, making that to be finished sand. This integrated process achieves high efficiency of recycling rates and zero emissions, turning waste into valuable resources.

Choosing the Right Recycling Approach

For sorting single-material waste, a single piece of equipment or a small set of machines suffices. For example, clean aluminum cans can be processed with just a single-layer eddy current separator, while iron scraps may only need an electromagnetic separator.

For complex, multi-layered waste—like mixed e-waste or slag with diverse metals and aggregates—integrated dry or wet separation lines are ideal. These complete production lines combine crushers for size reduction, screens for classification, eddy current separators for non-ferrous metals, magnetic separators for iron, washers for cleaning, and dewatering screens for moisture removal.

By matching the line to the waste type, Ruijie ensures the highest efficiency of recycling and purity in material recovery—achieving zero pollution and zero emissions, and turning even the most complex waste into reusable resources.

In a world grappling with waste, Ruijie’s series of equipment and sorting systems are game-changers. They turn inefficiency into precision, waste into wealth, and environmental harm into sustainability—proving that with the right technology, recycling can meet the challenges of our time.