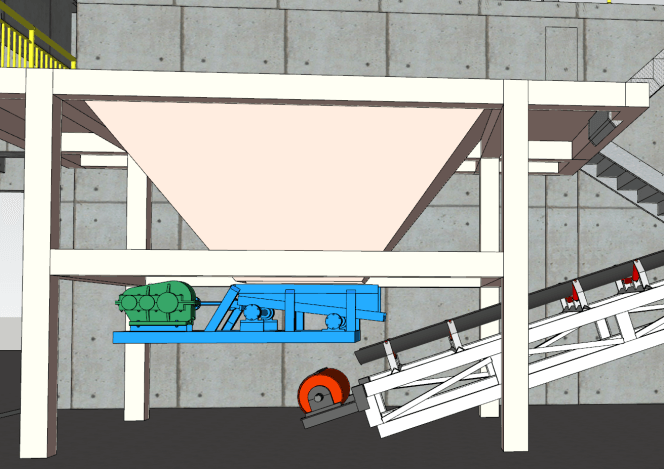

Reciprocating Plate Feeder Installation Instructions

1.The equipment can be installed on a horizontal concrete foundation, fixed with anchor bolts, or hoisted under the discharge port of the silo to ensure that it is firm.

2.Attention should be paid to the level of the body during installation.

3.Check whether the bolts are loose in each part after installation, and tighten them if so.

4.Configure power cords and control switches according to the power of the equipment, and carry out grounding protection.

5.After the inspection is completed, the no-load test machine is carried out, and the test machine can be produced if the test machine is normal.

Reciprocating Feeder Troubleshooting?

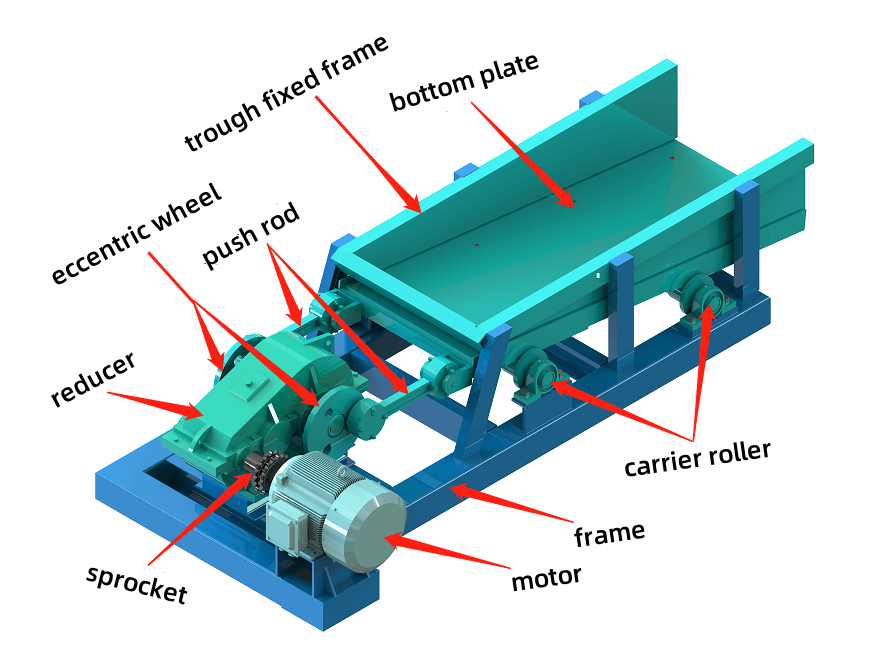

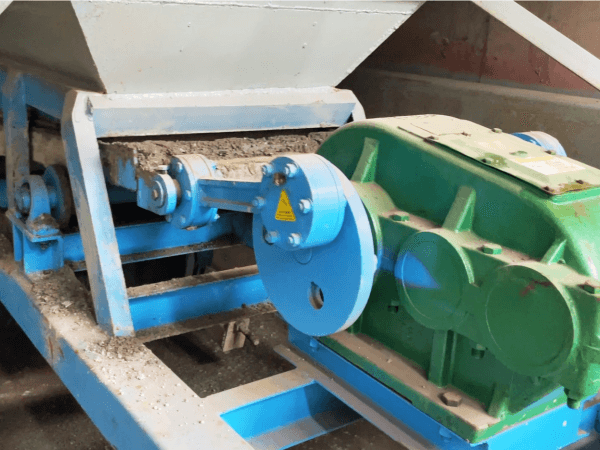

1.The push rod does not operate smoothly

Cause: Bearing damage

Solution: Replace the bearing (model 6308). Remove the push rod, open the bearing end cover, and replace the bearing.

2.The roller does not rotate

Cause: Bearing seat damage

Solution: Replace the bearing housing (model UCP210). Lift or lift the bottom plate slightly, remove the fixing bolts of the roller bearing seat, take out the entire roller, and install and fix it according to the original hole position after replacing the bearing seat.

If you could not solve the problems, just ask us for technical support.