In today’s world, resource scarcity and environmental protection are pressing issues—and metal recycling, particularly ferrous and non-ferrous metal recycling, has become more crucial than ever. It’s essential that we focus more on this practice and understand how to implement the recycling process.

What are Ferrous and Non-Ferrous Metals?

- Ferrous metals: These are metals that contain iron as a main component, known for their strength, durability, and magnetic properties. Magnetic makes them easier to separate during recycling. Common examples include steel, cast iron, and wrought iron.

- Non-ferrous metals: Unlike ferrous metals, non-ferrous metals do not contain iron. They have unique properties such as high conductivity, corrosion resistance, and low weight, making them valuable in many industries. Examples of non-ferrous metals include aluminum, copper, zinc, tin, and lead. Due to their extensive use, non ferrous scrap metals are vital to the metallurgy industry.

Why We Recycle Ferrous and Non-Ferrous Metals

- Resource conservation: Mining raw metals consumes massive energy and resources. Recycling reduces the need for new mining—critical for non ferrous metal, as its reserves are scarcer than ferrous metals.

- Environmental protection: Mining and smelting release pollutants (e.g., greenhouse gases, heavy metals). Recycling cuts emissions significantly; for example, recycling aluminum saves 95% of primary production energy and lowers greenhouse gases.

- Economic benefits: Recycled metals reduce manufacturing costs and create value. The non-ferrous metal recycle/recovery market is growing, bringing new business opportunities.

What are They Used in Our Daily Life?

- Ferrous metals: They are widely used in construction, such as in the construction of buildings and bridges. Steel is also used in the manufacturing of automobiles, home appliances, and tools. For example, the frame of a car is mainly made of steel.

- Non-ferrous metals: Aluminum is used in the production of beverage cans, window frames, and aircraft parts due to its light weight. Copper is an excellent conductor of electricity, so it is used in electrical wires and cables. Zinc is used for galvanizing steel to prevent corrosion, and it is also used in the production of batteries.

How to Reuse the Scrap

The process of reusing metal scrap mainly includes three steps: collection, sorting, and processing. The key step is sorting, which requires the use of professional separation machines.

1. Collection: Metal scrap is collected from various sources, such as households, industries, and construction sites. This can be done through garbage classification systems and scrap collection centers.

2. Sorting: This is a critical step to ensure the purity of the recycled metal, and different metals require targeted sorting equipment.

Sorting for Ferrous Metals: Rely on magnetic separators (utilizing ferrous metals’ magnetic property) with different models for varied scrap sizes

- Wet drum magnetic separator: Suitable for separating fine-grained ferrous materials (e.g., iron ore particles) by combining magnetic force with water washing to remove impurities.

- Up-suction magnetic separator: Effective for lightweight, small ferrous scraps (e.g., tiny steel shavings) by using suction force to capture and separate the scrap.

- Electromagnetic Overband separator: Widely applied on conveyor belts to separate large/medium-sized ferrous metals (e.g., steel bars, iron blocks) from mixed waste streams.

Sorting for Non-Ferrous Metals: Adopt equipment tailored to non-ferrous metals’ physical properties.

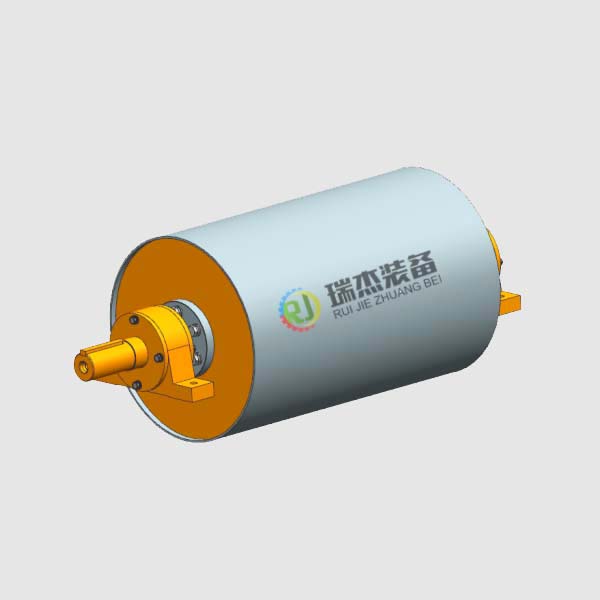

- Eddy current separator: The core equipment for non-ferrous sorting, which generates eddy currents in metals like aluminum and copper to create repulsive force, separating them from non-metallic materials.

- Jig concentrator: Used for separating specific non-ferrous metals (e.g., lead, zinc) and some ferrous scraps by leveraging density differences—heavier metals settle while lighter impurities are washed away.

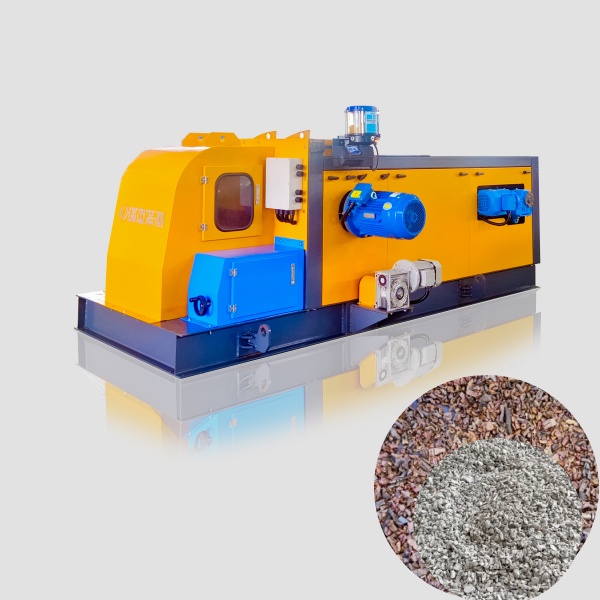

The equipment from Ruijie features high separation efficiency, stable performance, and low energy consumption, optimizing the sorting process for both ferrous and non-ferrous scrap.

3. Processing: After sorting, the metal scrap is processed into various forms (e.g., ingots, sheets) through melting, casting, and rolling. These processed metals then serve as raw materials for manufacturing industries (e.g., auto parts, electrical components).

Benefit of Reuse

- Energy saving: Recycling metals drastically cuts energy consumption—recycling copper saves about 85% of the energy needed for primary production, reducing reliance on fossil fuels and easing the energy crisis.

- Reduction of waste: Reusing metal scrap decreases landfill volume, saves land resources, and avoids soil/water pollution caused by long-term scrap accumulation.

- Promotion of sustainable development: As a key part of the circular economy, metal recycling balances economic growth and environmental protection—for the non ferrous metal industry, reuse extends resource life cycles and supports long-term sustainability.

Conclusion

Ferrous and non-ferrous metal recycling is vital for resource conservation, environmental protection, and economic development. Professional equipment (e.g., magnetic separators, eddy current separators) and RUIJIE’s high-quality non-ferrous metal separation machines are key to efficient recycling. Promoting metal recycling is essential for building a sustainable future.