The vibrating dewatering screen is a critical technology for efficient solid-liquid separation, with wide application from mining to wastewater management.

What is a Vibrating Dewatering Screen?

A vibrating dewatering screen is a specialized industrial equipment designed to remove moisture from solid materials, facilitating the separation of liquid and solid phases. It is commonly used in various industries such as mining, wastewater treatment, construction, food processing, chemical engineering, and environmental protection. By leveraging vibration technology, the screen effectively accelerates the dewatering process, ensuring that the final solid product meets the required moisture content standards.

By combining vibration mechanics and screening technology, it accelerates water drainage while retaining solid particles, making it indispensable for sustainable resource recovery and waste management.

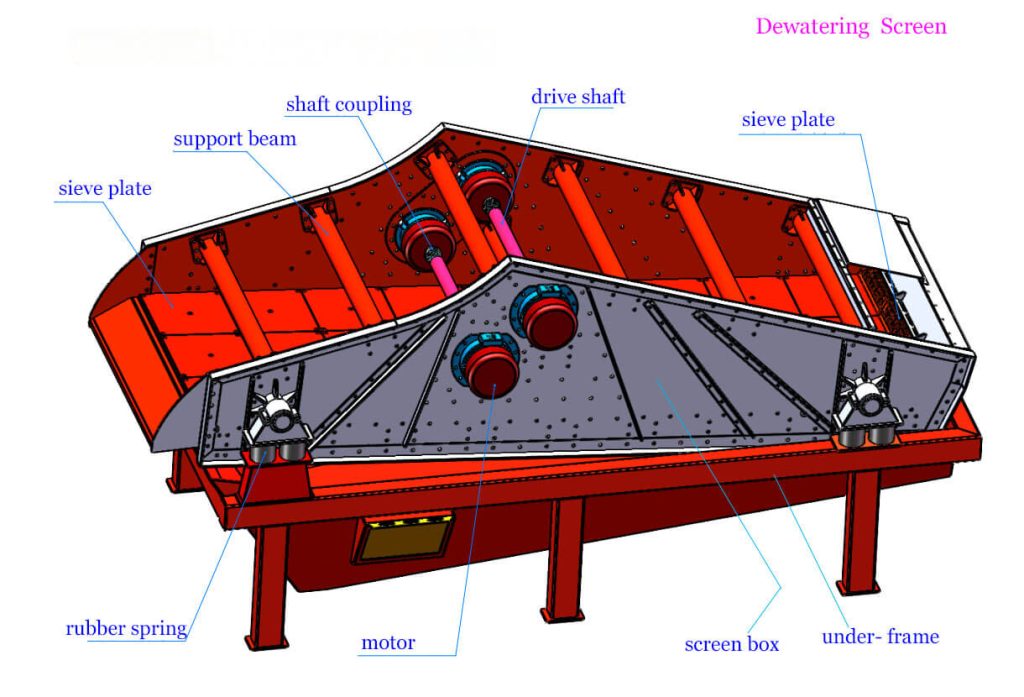

Structure of Ruijie Vibrating Dewatering Screen

Ruijie’s vibratory dewatering screens are engineered with precision and durability in mind. The key components include:

- Vibrating Motor: The heart of the screen, providing the necessary vibration force to move the materials across the screen surface. Ruijie uses high-quality vibrating motors that offer stable and adjustable vibration intensity.

- Sieve plate: made of special resin have stronger wear resistance and toughness, the screen mesh is responsible for filtering out the liquid while retaining the solid particles.

- Frame Structure: The large side plates are made of high-strength and high-toughness steel plates; the support beams are made of large-diameter seamless pipes, featuring high strength and high toughness;

- the steel components are fabricated by combining riveting and welding.

- Rubber Spring: Absorbs shock and stabilizes operations during intense vibrations.

Working Principle of Vibrating Dewatering Screens

The dewatering screen working principle relies on the combination of vibration and gravity:

- Vibration Generation: The motor creates high-frequency, low-amplitude vibrations, causing materials to fluidize on the screen surface.

- Solid-Liquid Separation: Water drains through the screen mesh, while solids move toward the discharge end due to the vibratory motion.

- Gravity-Assisted Drainage: Sloped screen decks enhance water flow, while adjustable vibration intensity optimizes dewatering efficiency for different materials.

The continuous vibration helps to prevent the screen from clogging and ensures efficient dewatering, and this mechanism ensures rapid dehydration with minimal energy consumption.

Applications of Vibrating Dewatering Screens

Dewatering screens are versatile across industries, offering tailored solutions for solid-liquid separation with measurable efficiency gains:

1. Mining & Mineral Processing

- Tailings Dewatering: Reduces moisture in iron ore, copper, or coal tailings from 20% to 10%, enabling dry stacking and minimizing environmental risks.

- Mineral Concentrate Processing: Dehydrates copper or gold concentrates, improving smelting efficiency and reducing transportation costs.

- Coal Washing: Separates water from coal slurry, achieving up to 95% water recovery for reuse in processing.

2. Wastewater & Sludge Management

- Municipal Sludge Treatment: Processes sewage sludge to 80% dryness, facilitating cost-effective incineration or landfill disposal.

- Industrial Effluent Handling: Treats oily sludge from refineries or chemical plants, recovering hydrocarbons and reducing hazardous waste volume by 70%.

3. Construction & Aggregates

- Sand Drying: Dewaters crushed sand to below 5% moisture content, ensuring high-quality concrete production.

- Recycled Aggregate Processing: Removes water from crushed concrete or asphalt, meeting strict sustainability standards for reuse in construction.

4. Food & Agriculture

- Starch and Sugar Production: Reduces moisture in starch granules or sugar beet pulp to 10–15%, lowering energy costs in downstream drying processes.

- Animal Feed Processing: Dehydrates agricultural byproducts (e.g., soybean meal) for stable storage and transportation.

5. Chemical Industry

- In chemical processing: Separates liquids from solid chemicals, dewatering materials like fertilizers, pigments, and catalysts, enabling the recovery of valuable products and reducing waste.

Advantages of Ruijie Dewatering Screens

- Eco-Friendly: Reduces wastewater volume and supports resource recycling.

- High Efficiency: With advanced vibration technology and optimized design, Ruijie vibrating dewaters can achieve high dewatering efficiency, reducing processing time and increasing productivity.

- Energy Saving: The energy-efficient vibrating motors consume less power, resulting in lower operating costs.

- Long Service Life: The use of high-quality wear-resistant materials and components ensures the durability of the screens, minimizing maintenance requirements and replacement costs.

- Flexibility: Adjustable vibration frequency, screen angles, and mesh sizes for diverse materials.

- Customization: Provides customized solutions based on clients’ specific needs, ensuring that the vibrating screen machine fits perfectly into their production processes.

Conclusion

Vibrating dewatering screens are indispensable in modern industrial processes, providing efficient and reliable solid-liquid separation solutions.

Ruijie, the dewatering screen supplier, its advanced designs, tailored for industries from mining to food processing, combine reliability, efficiency, and sustainability. Whether for sludge dewatering, mineral processing, or recycling applications, Ruijie’s technology ensures optimal performance while meeting the diverse needs of various industries.