Gravitational separation is an industrial method of separating two components in mineral processing. This method is particularly of great use in the recovery of expensive metals and minerals that are found in industrial wastewater.

The gravity separation method is used to separate a suspension or dry granular mixture where the components have different specific weights.

In this article, we will discuss what is enhanced gravity recovery, its principles, benefits, real-life use cases, and the equipment you can use to do that.

What is Gravitational Separation?

Gravitational separation is one of the oldest and most widely used methods of physical beneficiation, which is based on the differences in mineral density.

This makes this method suitably employed in the elimination of particles of various compositions from each other, particularly in the case of weighing worthwhile metals from a mixture of metals through flotation techniques. Its affordability, skill in usage, and the fact that it has close to no harm to the environment have remained a top choice in several industries, supporting the separation of major atmospheric components.

Historical Evolution Metal Recovery

Gravitational separation can be dated back to the ancient ages when gold panners used basic methods of directly crossing through rivers in an attempt to seek gold. The above basic processes have since developed into reasonable mechanisms through technological advancement over the centuries.

More improvements were recorded in the 19th and 20th centuries with the introduction of jigs, spirals, and shaking tables to boost their effectiveness for large-scale exercises, optimizing the equation of separation efficiency. In the present era, these practices have been enhanced by including technological advancements, coming up with automation, and precision practices to suit the industry.

Fundamental Principles of Gravitational Separation

Indeed, the basic mechanism on which the gravitational separation process is based lies in the fact that particles with different densities are likely to respond differently to gravitational force.

When such forces are applied to a mixture, heavier particles of the mixture will sediment in comparison with lighter portions or particles.

These factors include the size and shape of the particles, besides the medium in which they are located, as well as the velocity of the flow.

These principles are employed in equipment that is intended for gravity separation to facilitate patterns of materials’ segregation depending on the use density.

Applications in Industrial Waste Management

In the industrial waste management practice, gravitational separation is an essential process for recovering metals from slag, ASR, and IBA, among others, utilizing the principles of turbulent flow.

Still, if metals are separated properly from the waste stream, industries would cut negative effects on the environment, recover resources, and increase profitability.

For instance, the recycling of copper, silver, and other valuable metals out of industrial wastes means that the natural sources are preserved and the environmentally destructive mining is done to a lesser extent.

Overview of Gravitational Separation Equipment

Substances and materials that may be subjected to gravitation sorting differ greatly, which is why there is a vast array of equipment used for gravity separation:

- Jig Concentrators: They use water flow that is pulsating to classify material based on relative density.

- Spiral Separators: Uses helical channels for the separation of particles with the help of flowing film separation.

- Shaking tables: They use both the force of vibration and water flow to do the separation.

- Centrifugal Concentrators: Expand higher levels of gravitational forces to help with the separation of fine particles.

These products have their benefits, and the specific equipment to be used depends on the size of the particles that are required, the required quantity per unit of time, and the difference in the specific gravity of the materials.

Brands like Ruijie Equipment provide the industry with more effective equipment used in the gravitational separation process, which makes it practical and sustainable.

Ruijie-Equipment’s Innovative Solutions

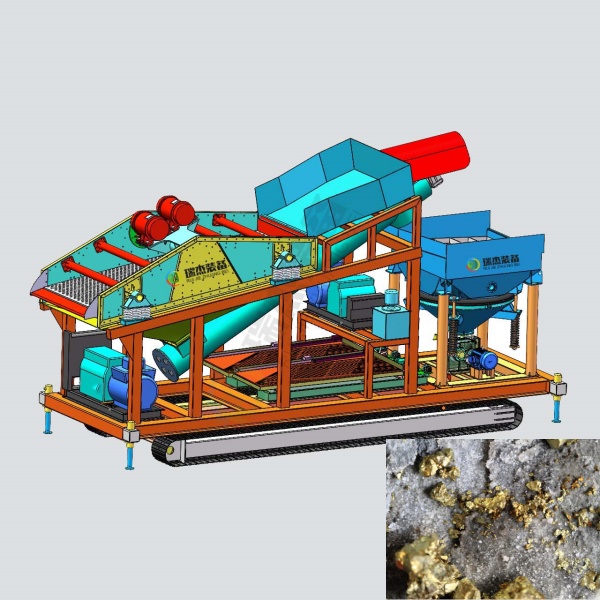

Ruijie-Equipment traces its roots to 2004 and focuses on the manufacturing of machinery for metallurgical waste recycling, more specifically metal recovery. Their product lineup includes:

- Gravity Sorting Machines: Gravity Sorting Machines are engineered for high-performance separation of metals from materials like copper, silver, tungsten, and incineration bottom ash (IBA).

- Magnetic Separators: Are devised to employ magnetic force to make ferrous metals pick out from the waste stream to increase the purity of recycled products.

- Screening Machines: Screening Machine help in the separation of materials based on size so that further separation becomes efficient.

- Conveying Systems: Design and implement an efficient way of moving materials from one stage of the separation process to the other.

- Crushing Equipment: Avails to change the nature of the waste content by reducing its size and thus enhancing the ability of the systems in the separation process.

It is very clear from the information presented that Ruijie-Equipment has embraced innovation in its products and services, bearing in mind that it offers standardized service delivery throughout the industry. They use the best technologies and a lot of precision in the engineering of the equipment to increase the efficiency of the separation process, as well as lower the costs of operations while promoting responsible use of our natural resources.

Advantages of Implementing Gravitational Separation

The method that involves the use of gravitational separation techniques has the following advantages:

- Efficiency: Owing to its procedural simplicity, comminution followed by gravitational separation is cheaper to perform than some of the more complicated techniques of separation.

- Environmental Sustainability: As it provides a means of recycling important metals from waste, gravitational separation lessens the use of new raw materials, hence preserving the environment and promoting the diffusion of sustainable practices.

- Capacity: By using high-tech gravitational separation, the equipment can handle tremendous loads of materials and, within a short time, provide significant yields of valued parts.

- Flexibility: Gravitational separation techniques can be utilized on various types of materials in various industries, inclusive of mining, ore processing, waste elimination, and scrap recycling.

Frequently Asked Questions (FAQs)

What is gravitational separation, and how does it work?

Gravitational separation is a density-based method that separates materials based on their weight. Heavier metals settle faster, allowing for efficient recovery from industrial waste.

Why is gravitational separation important for industrial waste management and the separation of major atmospheric components?

This technique helps recover valuable metals like copper and silver from industrial waste, reducing environmental impact and promoting resource sustainability.

What types of equipment are used in gravitational separation?

Key equipment includes jig concentrators, spiral separators, shaking tables, and centrifugal concentrators—each designed for specific material sizes and densities.

Conclusion

It is worth mentioning that gravity separation continues to be one of the primary processes in mineral processing and the disposal of industrial waste. For this reason, it is of great value to seek out valuable metals in organic mixtures, which may consist of food wastes or other materials. Ruijie-Equipment has devoted itself to the research and development of equipment that enables industries to adopt efficient and sustainable gravitational separation.