A sand washer machine is a crucial piece of washing equipment, also as a conveying equipment, used to remove impurities such as clay, silt, and debris from sand, enhancing its quality and usability.

Sand Types

- River Sand

Natural sand formed by river erosion, featuring rounded particles and low clay content (typically ≤3%).

Widely used in construction concrete and mortar as a high-quality natural aggregate. - Tailings Sand

Waste residue from mineral processing, containing metal micro-particles and chemical residues.

Requires intensive washing to remove hazardous components before safe recycling. - Recycled Aggregate Sand

Crushed from waste concrete, often with residual cement paste coatings.

Washing requires mechanical removal of adhered paste, offering >30% cost savings over natural sand. - Natural Sand

Sand formed by natural weathering or water erosion (e.g., river/mountain sand).

Composition varies by source; some require washing to remove impurities before use.

The sand quality directly impacts the strength and durability of concrete, mortar, asphalt, and precast elements. Impurities weaken bonds and increase water demand. Clean sand is vital for:

- High-strength concrete production.

- Plastering and rendering.

- Brick and block manufacturing.

- Glass production.

- Foundry sand.

- Landscaping and recreational surfaces.

Clean sand can be obtained through the sand washing process, removes impurities (clay, silt, dust) through mechanical agitation and water immersion, then grade and dewater. In the washing processing, sand washer machine is crucial.

Types of Sand Washers

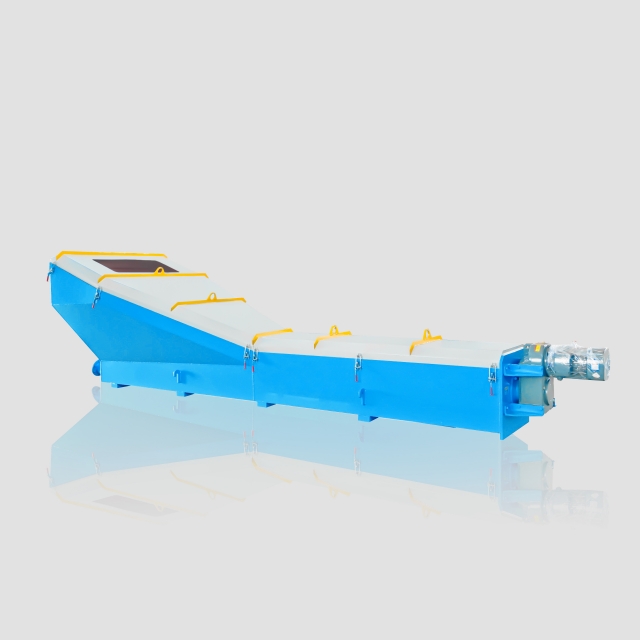

- Spiral Sand Washer (Screw Sand Washer Machine)

- Working Principle:

Material moves along an inclined trough while rotated by spiral blades. Counter-current water flow carries away sludge and impurities. Cleaned sand is discharges from the outlet. - Features:

Gentle washing with low sand breakage rate.

Combines washing, dewatering, and grading functions. - Applications:

Ideal for medium-fine sand with moderate clay content, such as river sand, crushed sand. Widely used in sand and gravel plants, mineral processing plants, hydropower ect.

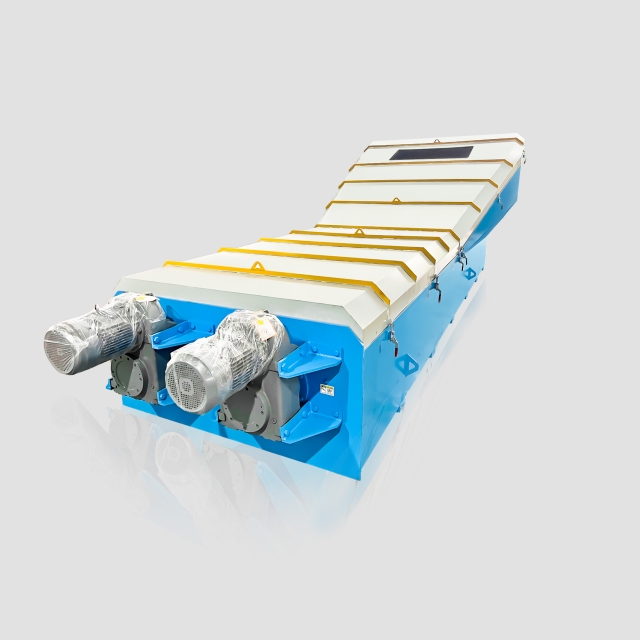

2. Bucket Wheel Sand Washer

- Working Principle:

Buckets on a rotating wheel scoop material, scrub it intensively, and discharge sludge through side outlets. Cleaned sand is dewatered via screens. - Features:

High-intensity scrubbing for stubborn clay.

Large processing capacity, suitable for continuous operation.

Integrates aggressive washing and efficient dewatering. - Applications:

Best for high-clay-content or coarse materials,such as mining tailings, weathered sand. Essential in large-scale aggregate plants.

3. Trommel Scrubber (Rotary Scrubber)

- Working Principle:

Material tumbles inside a rotating drum with water jets, removing impurities through friction. - Features:

Simple structure, low maintenance.

Effective for extremely sticky clay. - Applications:

Construction waste recycling, high-clay sand/gravel pretreatment.

4. Vibrating Sand Washer Machine

- Working Principle:

Vibrating screen surface tosses material while water sprays remove sludge. - Features:

Simultaneous washing and precise grading.

Ideal for fine particle control. - Applications:

High-grade sand requiring strict gradation, such as glass sand, foundry sand.

How to Select a Right Sand Washing Machine?

When choosing a sand washer machine, several factors come into play:

1. Analyze material characteristics, including particle size and clay content.

2. Evaluate production scale, such as process capacity and output demand.

3. Consider operational costs, for example, water consumption,energy & maintenance and

initial investment.

4. Application-specific requirements: high-grade sand, construction waste/recycling ,mining tailings or weathered sand.

5 .Site and environmental factors, space constraints, environmental regulations

6. Compare Machine Features

For large – scale mining or construction projects, spiral sand washers are preferred due to their high processing capacity. If space is limited or the production volume is small, a small sand washing machine or a bucket wheel sand washing machine would be more appropriate. Additionally, considering the sand cleaning machine price is essential to ensure cost – effectiveness.

Conclusion

The significance of sand washers machine cannot be overstated. They improve the quality of sand, making it suitable for high – end construction and industrial applications. Clean sand enhances the strength and durability of concrete and other building materials, ensuring the safety and longevity of structures.

In conclusion, sand washers, in their various forms, play a vital role in the sand processing industry. Understanding their types, applications, and selection criteria is crucial for maximizing efficiency and quality in any sand – related project.