The Use Sites of The Stone Hammer Crusher

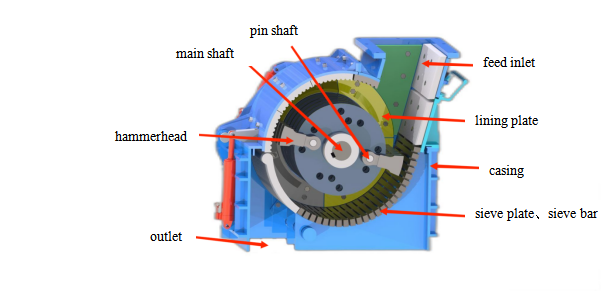

The industrial stone hammer crusher can produce discharged materials with uniform particle size. By adjusting the equipment parameters, the size of the crushed material can be controlled to meet the requirements of subsequent processing or utilization, which is essential for the recovery of useful components in slag.

Ruijie crushing equipment has high crushing efficiency and can process large quantities of slag quickly. The crushed material has a uniform particle size, which is conducive to subsequent processing and application. In addition, the equipment is easy to operate and has low maintenance costs, which can save enterprises a lot of manpower and material resources.