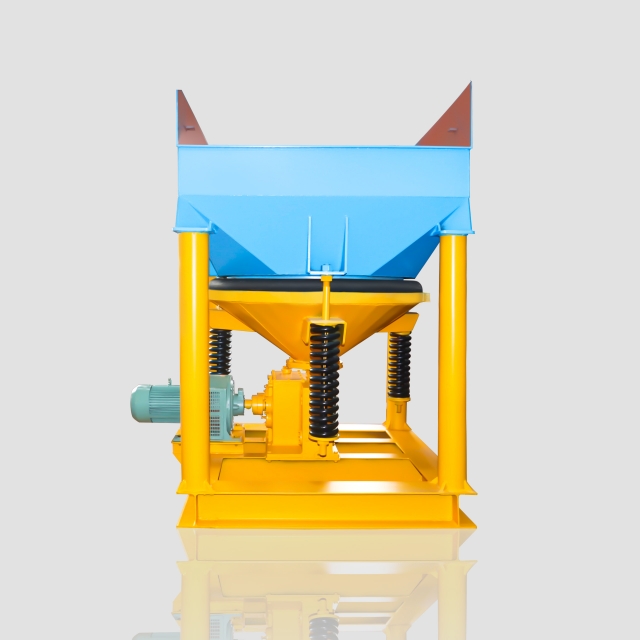

What is A Jig Separator?

A jig separator machine is a gravity-based mineral processing device designed to separate particles based on density differences, used mainly in the mining industry for mineral processing. Originating in the 19th century for coal washing, it has evolved to handle metals, non-metallic minerals, and recycled materials.

Ruijie jig concentrator is developed for precious metals separation in slag processing, ore processing, and other industries.

Structure of a Jig Separator

Key Components

Ruijie Jig Separator is consist of Jigging chamber, screen, diaphragm, spring, seamless, motor, coce bucket, reducer, features with compact constructure, small footprint.

Structure Advantages

Body & Drive System: Supports operation with screens and diaphragms.

Control System: PLC modules enable real-time adjustments for parameters like stroke and frequency.

Discharge Mechanism: Separates heavy minerals from light gangue, such as gold, copper, ect.

Jigging chamber:The large jig chamber area allows materials to spread thinly, enhancing separation efficiency and metal recovery.

Cam reducer:The cam reducer is independently developed and optimized for the slag processing industry, rigorously tested to ensure superior performance.

Diaphragm:And the diaphragm of the jig concentrator is made from specialized materials, offering excellent resistance to corrosion and abrasion for long-lasting performance.

Removable screen:An optional removable screen cabinet for the jig machine is available, making material cleanup and maintenance more convenient.

Jig Machine Working Principle

What is Gravity Separation

Gravity separation is also called relative gravity separation as it separates particles due to their relative response to a driving force. This is controlled by factors such as particle weight, size and shape.

Of the gravity separation processes, the spiral concentrators and circular jigs are two of the most economical due to their simplicity and use of space.

Jig concentrators are devices used mainly in the mining industry for mineral processing, to separate particles within the ore body, based on their specific gravity (relative density).

Working Principle of the Jig Machine

In a jig’s operation, particles of similar size, typically crushed and screened beforehand, are fed onto the jig bed. A pulsating water column surges upwards, suspending the particles in water. When the pulse subsides and the water returns to its initial level, the particles start to settle. Due to gravitational forces, those with higher density sink faster, concentrating at the bottom of the jig bed. Subsequently, the material can be separately extracted according to density, with the denser portion being the desired mineral and the rest discarded as tailings.

Unlike traditional sine wave jigs, the Ruijie Sawtooth Wave Jig features a fast upward water flow and slow downward water flow. This unique pulsation pattern enhances bed looseness, reduces suction effects, and allows heavy minerals to settle more efficiently, improving recovery rates by 3-5%.

Application of Jig Machine In IBA Sorting

Incineration bottom ash (IBA) is a form of ash produced in incineration facilities. This material is discharged from the moving grate of municipal solid waste incinerators.

As reported , the German LAGA regulations have to ensure environmentally safe ash residue management and resource recovery through scientific classification and rigorous pre-treatment, balancing industrial needs with ecological protection. That means it is crucial for proper treatment of incineration bottom ash(IBA).

While jig machine play an important role in the IBA sorting, separating non-ferrous metal or heavy components from IBA material.

Other Applications

The gravity separator machine also can be used in

Mining Industry, such as metalliferous ore separation, non – metallic ore processing.

Construction and Building Materials Industry, such as sand and aggregate processing, ceramic raw material processing.

Environmental Protection and Resource Recycling Fields, such as solid waste treatment, tailings reuse.

Including chemical industry, water conservancy and power industry.

Since Ruijie sawtooth wave jig concentrator is featured with the character of adjustable stroke and jig frequency, watering saving, long continuous working time, high recovery rate of fine-grain materials, it is widely favored by various industries, becoming the top choice for gravity separation machine.

Conclusion & Future Trends

The mineral jig separator excels in efficiency and sustainability. Future innovations focus on:

Smart Control: AI-driven parameter adjustments.

Fine Particle Processing: High-frequency vibrations for finer grains.

Through optimized design and technological advancements, jig separators will remain pivotal in mining and environmental industries. Contact Ruijie Equipment for more detailed technology information and professional design solution.